The 9-Minute Rule for Plant Conveyors And Systems

Table of ContentsThe Ultimate Guide To Plant Conveyors And SystemsEverything about Plant Conveyors And SystemsTop Guidelines Of Plant Conveyors And SystemsThe 45-Second Trick For Plant Conveyors And SystemsPlant Conveyors And Systems for Dummies

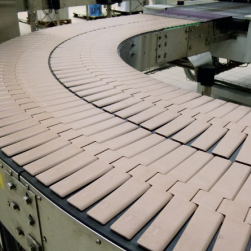

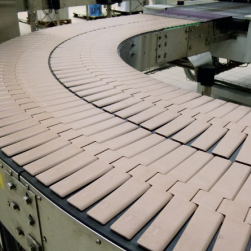

Released On: November 11, 2019 With numerous various alternatives, it can be hard to understand what kind of conveyor systems to use in your warehouse automation. Right here are 20 usual sorts of conveyors. If you need help selecting systems for your storehouse, contact DCS. This is possibly what you visualize when you consider a conveyor.It is constructed at a mild decrease so components slide downward on their very own. This resembles a gravity roller conveyor except a chain or belt is utilized to make the rollers turn on their own, so they do not need to be improved a decrease. In some cases they can also go uphill.

Bucket conveyor systems are used to move product vertically, by scooping it with a collection of buckets connected to a belt, chain, or wire. Essentially, think of rows of steel rounds on a table that can transform and also turn in any type of instructions.

Our Plant Conveyors And Systems Ideas

Instead of having rollers or a belt, they have relocating chains to carry products. There is a whole family members of conveyors that lug their load underneath them instead of on top of them.

In some cases, as with the Power-and-Free Conveyor, they have two tracksone mechanized and also one not mechanized. Turn a cart conveyor upside down, affix it to the flooring rather of the ceiling, as well as you have actually got an inverted monorail. This conveyor vibrates somewhat to move mass product along it.

Plant Conveyors And Systems Can Be Fun For Everyone

There are additionally various other associated tools that make use of a chain to drag things such as a tubular drag conveyor. These conveyors make use of a vacuum cleaner or air pressure to relocate material.

They lift them up to a different degree of the storage facility. They are not huge enough to lift individuals, nonetheless. These are comparable to a roller conveyor other than with little, private wheels rather than long, cylindrical rollers. Strolling Beam of light conveyors move product incrementally along the conveyor utilizing moving discover this info here and fixed assistances.

If you require help selecting a conveyor system, let us understand. We have more than 35 years of experience servicing projects big (up to $30 million) and tiny.

Little Known Questions About Plant Conveyors And Systems.

Intro The full guide to conveyor systems on the web. Conveyor System Demands Kinds of Conveyor Equipments How Does a Conveyor System Work?

Load Capacity: Once the system has actually been laid out more information and provided a pattern, it needs to be established what will certainly be the amount of products it can carry - Plant Conveyors and Systems. Overwhelming a system can harm it or cause it to quit in the middle of its procedure. Aspects that affect the load capacity are general size and bed width as well as the drive system.

About Plant Conveyors And Systems

Motion of powdered, granular, as well as chip type materials can have dust develop, which is taken into consideration in system style and may necessitate some type of filtration. Just like other sharing systems, a cautious examination of the features of the material is called for. Setup: Communicating systems been available in a broad selection of shapes, layouts, sizes, and also forms.

Considering that each system is developed to fit an unique application, it would be impossible to cover all of the various setups. What is necessary to comprehend is that navigate to this site there are very couple of constraints on including a communicating system, despite the application. Drive System: The drive of an automated communicating system is the power that relocates products.